Welke processen biedt Alro Group aan?

WIJ STEMMEN ONZE PROCESSEN AF OP JOUW VRAAG!

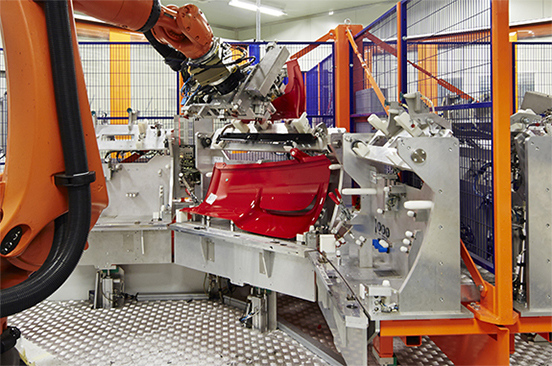

Bij Alro Group zijn we trots op onze moderne productielijnen- en processen. Dankzij die state-of-the-art processen kunnen we kwalitatieve, organische verflagen aanbrengen waaronder: natlak, poederlak en kataforese (KTL). Samen met jou bepalen we welke coating het meest geschikt is voor jouw specifieke project.

Bij ieder proces zorgen we steeds voor een voorbehandeling. We wassen eerst alle onderdelen om onzuiverheden te verwijderen. Bij metalen onderdelen brengen we ook een conversielaag aan die zorgt voor corrosieweerstand en een goede hechting op de metalen onderdelen. Daarna brengen we de verflaag aan. De manier waarop dat gebeurt, is afhankelijk van jouw wensen en het proces dat daarvoor nodig is. Vervolgens wordt de lak uitgehard. Tot slot kunnen we voor de onderdelen die KTL gelakt zijn een extra laag aanbrengen om naast de corrosiebescherming ook andere eigenschappen aan de coating toe te voegen. Dat kan gaan van de verbetering van fysieke eigenschappen van de coating tot het visuele aspect van de coating.

Ook de assemblage van de gelakte onderdelen nemen wij voor onze rekening. Die assemblage kunnen we zowel automatisch als manueel doen. Bij complexere onderdelen gebruiken we beide technieken.

We voeren de verschillende processen uit in onze vijf coatingbedrijven. Die zijn gelegen in zowel West-Europa als in Centraal-Europa. Bovendien zijn de mogelijkheden eindeloos. Elke dag verwerken we meer dan 100.000 producten in 1.000 kleuren met ruim twintig coatinginstallaties. Onze capaciteit is dus enorm.

Uiteraard investeren we voortdurend in nieuwe processen om aan jouw specifieke wensen te blijven voldoen. Daardoor garanderen we zowel een hoge flexibiliteit als een hoge coatingkwaliteit.