WHAT PROCESSES DOES ALRO GROUP OFFER?

We customise our processes to your requirements!

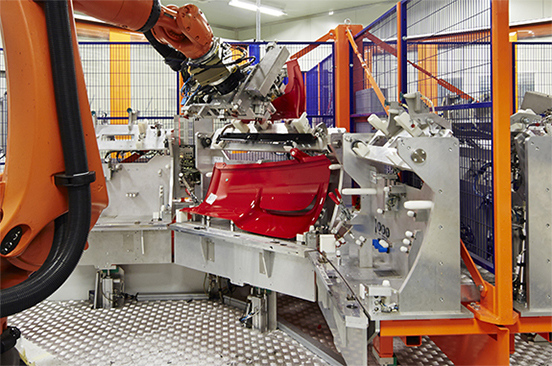

Alro Group is proud of its modern production lines and processes. Our state-of-the-art processes enable us to realise high-quality organic coatings including wet painting, powder coating and e-coating (KTL). We work with you to identify the optimal coating for your specific project.

Every process starts with pretreatment. First, all parts are wet cleaned to remove any impurities. Metal parts are given a conversion coat for better corrosion resistance and paint adhesion. Next, we apply the paint coat. How this is done depends on your requirements and the corresponding processes. Once the coating has cured, e-coated parts (KTL) may be given an additional coat to make other physical and visual improvements in addition to their corrosion resistance.

We can also handle the automated or manual assembly of the coated parts for you. We may also combine both approaches for more complex parts.

All these different processes are carried out by our five coating sites in Western and Central Europe. What’s more, the possibilities are countless. We process over 100,000 products in 1,000 different colours with more than twenty coating systems every day, so we have a huge capacity.

Of course, we also keep investing in new production processes to satisfy your specific requirements. This allows us to guarantee optimal flexibility and exceptional coating quality.